In the automotive industry, ensuring the optimal performance of fuel injectors is crucial for engine efficiency and longevity. To meet the high standards required in modern automotive manufacturing, a precise and reliable inspection process is essential. Traditional methods, often reliant on manual testing and visual inspection, can be time-consuming and prone to inconsistencies.

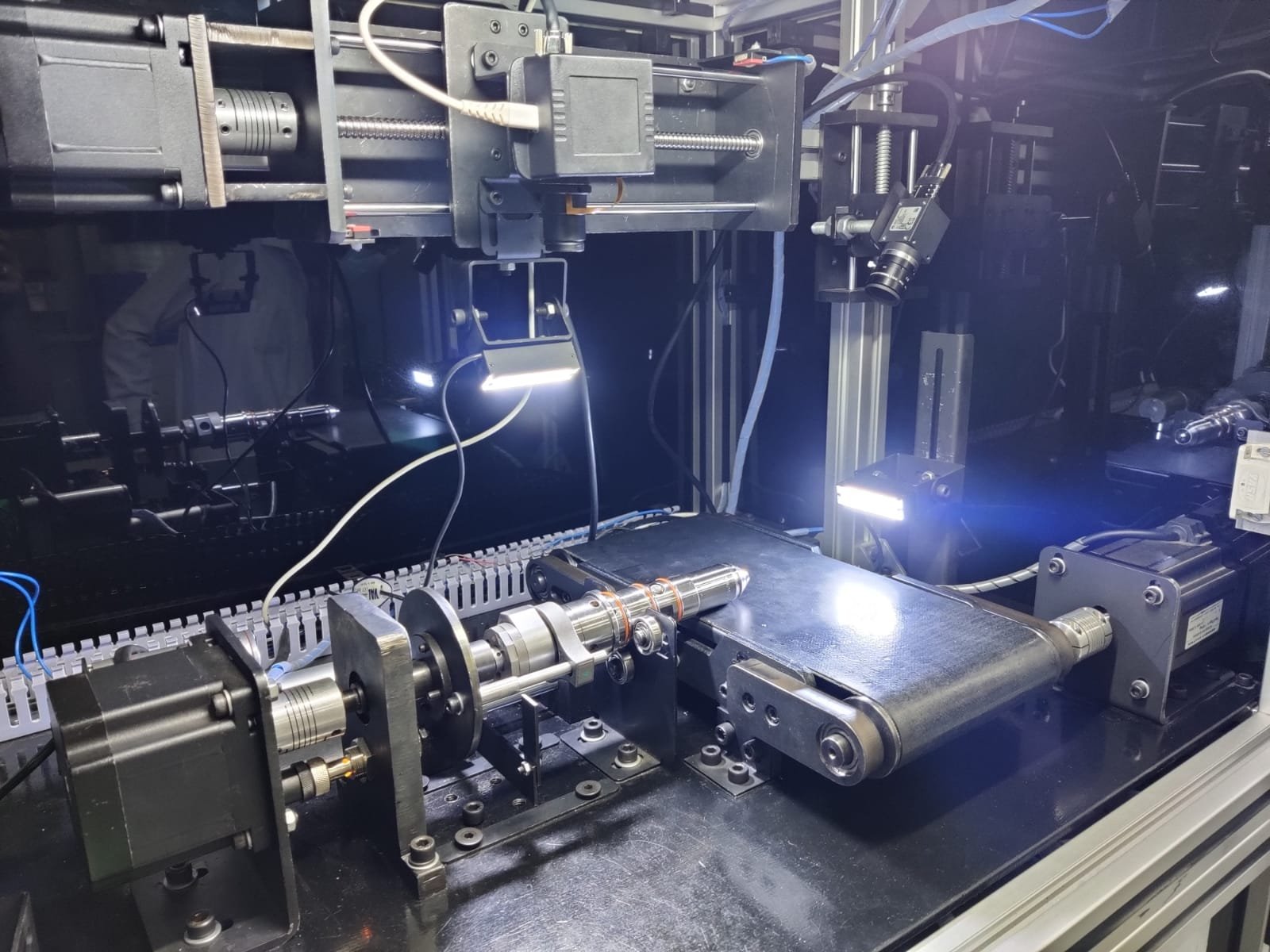

Introducing an advanced inspection machine equipped with AI-powered vision technology provides a cutting-edge solution for automating the evaluation of newly manufactured fuel injectors. By leveraging high-resolution imaging and machine learning algorithms, this system offers unmatched precision in detecting defects, verifying spray patterns, and ensuring that each injector meets the stringent quality criteria. The result is a faster, more accurate inspection process that improves manufacturing efficiency, reduces defects, and enhances overall product reliability.